Freeze-Dried Bacterial Packets Enable On-Demand Biocement Production

March 5, 2025

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

by American Chemical Society

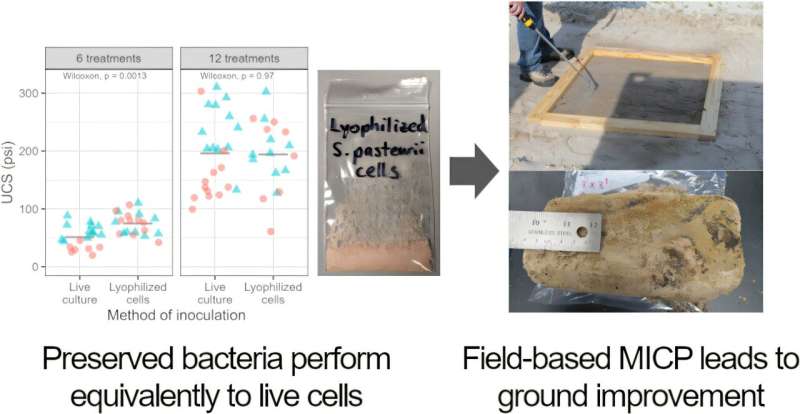

Cement manufacturing and repair could be significantly improved by using biocement-producing bacteria, but growing the microbes at construction sites remains a challenge. Now, researchers report a freeze-drying approach in ACS Applied Materials & Interfaces that preserves the bacteria, potentially allowing construction workers to ultimately use powder out of a packet to quickly make tiles, repair oil wells or strengthen the ground for makeshift roads or camps.

Soil stabilization and concrete repair are major challenges facing civil engineers. Recently, researchers have shifted their attention to a tiny bacterium called Sporosarcina pasteurii that can produce a form of calcium mineral called biocement. The microbes break down urea and form ammonium and carbonate. Then, with the addition of calcium, the result is calcium carbonate, which glues sand and soil particles together or repairs cracks in existing concrete structures.

To make biocement for construction projects, the bacteria currently must be grown onsite with special equipment and technical know-how. So, Maneesh Gupta and colleagues wanted to develop a way to preserve S. pasteurii in a shelf-stable format that would be easy for construction workers to use.

Gupta's team was inspired by manufacturers who freeze-dry biological components and add them to fertilizers. The researchers suspended the bacteria in different solutions and tested how well the microbes survived freezing. They found that sucrose protected the microbes best compared to other types of protectants. After freezing, the bacteria were dried and then stored in resealable plastic bags. Sucrose-treated S. pasteurii remained viable for at least three months.

Further laboratory testing showed that the sucrose-preserved, freeze-dried bacteria could be used to cement sand in 3D-printed cylindrical molds. The researchers prepared separate columns with play sand, like that used in children's sandboxes, and natural sandy soil taken from the ground. Then, when the columns were sprayed several times with calcium chloride and urea, the bacteria produced biocement. The biocement in the columns made with play sand was stronger than the biocement formed with soil, and most of the biocement samples could be removed from the play sand molds.

In another lab test, the team prepared columns of freeze-dried bacteria with natural sandy soil inside PVC pipes but did not remove the biocement from the pipes. The PVC columns made of both play sand and natural soil were stronger with exposure to more calcium chloride and urea.

In field tests, freeze-dried bacteria were applied to the surface of 3-foot by 3-foot (about 1-meter by 1-meter) plots, and urea and calcium chloride were sprayed on top. The freeze-dried bacteria made the top 3 inches (7.6 centimeters) of the ground stronger within 24 hours.

Although more work is needed, the researchers say this is the first demonstration that freeze-dried S. pasteurii remains viable and can make biocement, and it could be feasible for future deployment in the field.

More information: Matthew J. Tuttle et al, Shelf-Stable Sporosarcina pasteurii Formulation for Scalable Laboratory and Field-Based Production of Biocement, ACS Applied Materials & Interfaces (2025). DOI: 10.1021/acsami.4c15381

Journal information: ACS Applied Materials and Interfaces

Provided by American Chemical Society