Stretchable Electronics Empowered by 3D Printed Elastic Conductors

May 11, 2023 feature

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

- fact-checked

- peer-reviewed publication

- trusted source

- proofread

by Ingrid Fadelli , Tech Xplore

Three-dimensional (3D) printing continues to advance, and has had success creating a vast array of items, from toys and furniture to electronic components. As 3D printing equipment becomes more affordable, it may also soon allow for the creation of soft electronic components for wearable technology.

Despite its promise in this area, 3D printing has thus far seen little success in producing complex and flexible electronics. One key reason for this is that it is difficult to print solid-state elastic materials that can conduct electricity using existing inks.

Researchers from the Korea Institute of Science and Technology recently demonstrated their success in using 3D printing to create elastic components capable of conducting electricity. Their proposed printing strategy, outlined in a paper in Nature Electronics, could potentially pave the way toward the large-scale printing of multi-functional and stretchable components for wearable devices.

The team developed a new emulsion-based composite ink, which allowed for the creation of elastic conductors through 3D printing. This special ink consists of liquid components dispersed within a conductive elastomer; a rubber-like material that can conduct electricity.

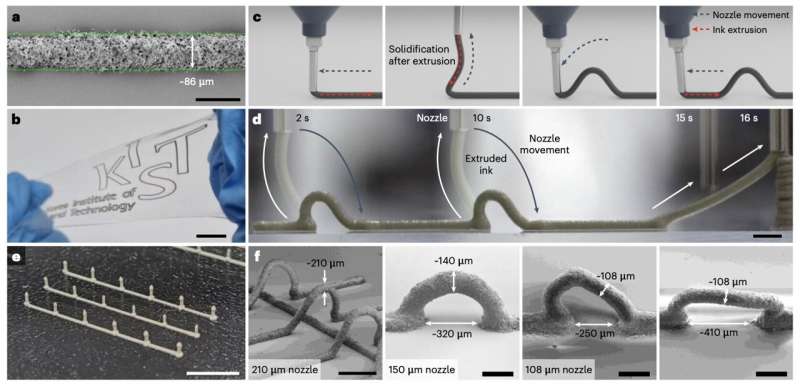

'Printing solid-state elastic conductors with three-dimensional geometries is challenging because the rheological properties of existing inks typically only allow for layer-wise deposition,' wrote Byeongmoon Lee, Hyunjoo Cho, and their colleagues in the paper.

'We show that an emulsion system - consisting of a conductive elastomer composite, immiscible solvent, and emulsifying solvent - can be used for the omnidirectional printing of elastic conductors. The viscoelastic properties of the composite provide structural integrity to the printed features - allowing freestanding, filamentary, and out-of-plane three-dimensional geometries to be directly written - and pseudo-plastic and lubrication behaviors that provide printing stability and prevent nozzle clogging.'

Compared to other inks commonly used in 3D printing, the composite ink created by the researchers has numerous advantageous properties; specifically, it has viscoelasticity, shear-thinning, and lubricating properties, which facilitate the printing of complex 3D structures.

'Printed structures of the intrinsically stretchable conductor exhibit a minimum feature size less than 100 μm and stretchability of more than 150%,' noted Lee, Cho, and their colleagues in their paper. 'The vaporization of the dispersed solvent phase in the emulsion results in the formation of microstructured, surface-localized conductive networks, which improve the electrical conductivity.'

To showcase the potential of their 3D printing approach and the emulsion-based ink they have designed, the researchers printed elastic interconnects and created a wearable temperature sensor with a stretchable display. This device performed well, and the same method could soon also be used to create a range of various other stretchable and conducting components.

In their paper, Lee, Cho, and their colleagues highlight the possibility of combining their approach with 3D scanning technologies to create soft electronics perfectly aligned with the shape of the human body, making it more comfortable for users to wear. Additionally, the ink they created could inspire the development of other emulsion-based inks that operate similarly but rely on different compositions and elastomers.

© 2023 Science X Network