New Method Generates Ammonia-Based Clean Hydrogen with Zero Carbon Dioxide Emissions

A new technology for the production of clean hydrogen from ammonia, without the use of fossil fuels, has been introduced by scientists. This innovation provides a greener alternative for hydrogen-powered vehicles and has promising applications in sustainable energy and transportation. The technology is demonstrated in the first Carbon-free Ammonia Decomposition Reactor created by the Korea Institute of Energy Research.

The historic feat of producing high purity hydrogen from ammonia has been achieved by the Korea Institute of Energy Research (KIER) in Korea, with the process completely zeroing out carbon dioxide emissions.

Dr. Jung Unho's research team from the Hydrogen Research Department of KIER has developed this pioneering technology for producing clean hydrogen in Korea. The methodology is rooted in ammonia decomposition and is completely fossil fuel-free. This breakthrough could set the stage for a more sustainable and green energy source that satisfies international standards for hydrogen-powered vehicles, without the carbon dioxide emissions associated with fossil fuel use.

Ammonia, a compound made of hydrogen and nitrogen, has a higher hydrogen storage density 1.7 times than that of liquefied hydrogen. In light of this, it's seen as the most cost-effective way to transport hydrogen. As it has already been used in fields like fertilizers for over a century, its infrastructure, handling, and safety standards are already well-developed. It's viewed as a viable solution for addressing the difficulties of storing and transporting hydrogen.

Ammonia's composition is just hydrogen and nitrogen which implies no carbon gets released when the hydrogen gets separated. The decomposition process requires heat energy of over 600℃, commonly supplied by fossil fuels, thereby resulting in carbon dioxide emissions. Consequently, a carbon-free energy source is necessary for the ammonia decomposition when producing clean hydrogen.

The left-over small quantities of hydrogen and ammonia from the decomposition reaction were used to produce hydrogen without resorting to fossil fuels.

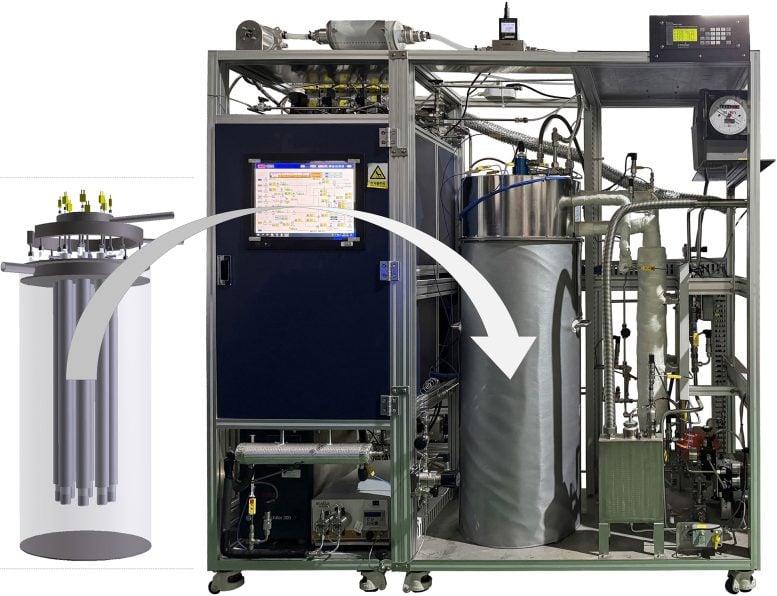

For generating pure hydrogen from ammonia, the decomposition of ammonia happens over a temperature of 600℃ using a ruthenium (Ru) catalyst. This is then followed by the purification of hydrogen through Pressure Swing Adsorption (PSA) technology. During this process, a residual gas mixture of nitrogen and hydrogen is generated and reused as a heating factor for the ammonia decomposition reactor. Nevertheless, the residual gas alone does not provide enough heat of reaction, thereby requiring additional heat to be incorporated.

Existing technologies usually use fossil fuels like natural gas (LNG) or liquefied petroleum gas (LPG) to supplement insufficient heat of reaction and thus release carbon dioxide emissions during combustion. However, the developed system allows the use of ammonia instead of fossil fuels to supply the required heat of reaction and inhibit carbon dioxide emissions at the source.

With the new system, high-purity hydrogen with over 99.97% purity is produced at a rate of 5 Nm3 per hour. The produced hydrogen contains an impurity concentration of less than 300ppm for nitrogen and less than 0.1ppm for ammonia. It adheres to ISO 14687, the international standard for hydrogen-fueled electric vehicles.

A significant milestone has been reached by the research team, with the successful demonstration of a 1kW fuel cell system for buildings. This system generates electricity without carbon dioxide emissions by using hydrogen extracted from ammonia. It was carried out together with the Doosan Fuel Cell Power BU and addresses the challenge of carbon dioxide emissions, typically associated with natural gas-based fuel cell systems. This shows the potential for power generation using clean hydrogen fuel cells.

According to lead researcher Dr. Jung Unho, the newly developed technology holds great significance as it allows for carbon-free hydrogen production using ammonia, filling a previous gap in this area. There is an expectation that it will find practicality in diverse areas that use clean hydrogen. In his remarks, he went on to say, “The combining of ammonia and fuel cells presents a viable option for powering eco-ships. And as we scale up, we can also make a significant impact in the clean hydrogen power sector.”

Meanwhile, this research was conducted with the support of Korea Southern Power Co., Ltd. (KOSPO).