Innovation in Lithium Production: A Game-changing Extraction Technique

Princeton researchers have developed a new lithium extraction technique using porous fibers that significantly reduces the time and land required for production. This environmentally friendly method, which separates lithium and sodium using evaporation and capillary action, has the potential to revolutionize the battery industry. Credit: Bumper DeJesus

Lithium, an essential element in electric vehicle batteries and energy storage systems, holds promise for a greener future. However, its production carries notable environmental implications. Extracting lithium from saline water demands substantial land and time, with large operations running into the dozens of square miles and often requiring over a year to begin production.

Now, researchers at Princeton have developed an extraction technique that slashes the amount of land and time needed for lithium production. The researchers say their system can improve production at existing lithium facilities and unlock sources previously seen as too small or diluted to be worthwhile.

The core of the technique, described in a paper recently published in Nature Water, is a set of porous fibers twisted into strings, which the researchers engineered to have a water-loving core and a water-repelling surface. When the ends are dipped in a salt-water solution, the water travels up the strings through capillary action – the same process trees use to draw water from roots to leaves.

The water quickly evaporates from each string’s surface, leaving behind salt ions such as sodium and lithium. As water continues to evaporate, the salts become increasingly concentrated and eventually form sodium chloride and lithium chloride crystals on the strings, allowing for easy harvesting.

In addition to concentrating the salts, the technique causes the lithium and sodium to crystallize at distinct locations along the string due to their different physical properties. Sodium, with low solubility, crystallizes on the lower part of the string, while the highly soluble lithium salts crystallize near the top. The natural separation allowed the team to collect lithium and sodium individually, a feat that typically requires the use of additional chemicals.

A Princeton research team has developed a new approach for concentrating, separating, and harvesting lithium salts. Credit: Bumper DeJesus

“We aimed to leverage the fundamental processes of evaporation and capillary action to concentrate, separate, and harvest lithium,” said Z. Jason Ren, professor of civil and environmental engineering and the Andlinger Center for Energy and the Environment at Princeton and the leader of the research team. “We do not need to apply additional chemicals, as is the case with many other extraction technologies, and the process saves a lot of water compared to traditional evaporation approaches.”

Limited supply of lithium is one obstacle to the transition to a low-carbon society, Ren added. “Our approach is cheap, easy to operate, and requires very little energy. It’s an environmentally friendly solution to a critical energy challenge.”

Conventional brine extraction involves building a series of huge evaporation ponds to concentrate lithium from salt flats, salty lakes, or groundwater aquifers. The process can take anywhere from several months to a few years. The operations are only commercially viable in a handful of locations around the world that have sufficiently high starting lithium concentrations, an abundance of available land, and an arid climate to maximize evaporation. For instance, there is only one active brine-based lithium extraction operation in the United States, located in Nevada and covering over seven square miles.

The string technique is far more compact and can begin producing lithium much more quickly. Although the researchers caution that it will take additional work to scale their technology from the lab to an industrial scale, they estimate it can cut the amount of land needed by more than 90 percent of current operations and can accelerate the evaporation process by more than 20 times compared to traditional evaporation ponds, potentially yielding initial lithium harvests in less than one month.

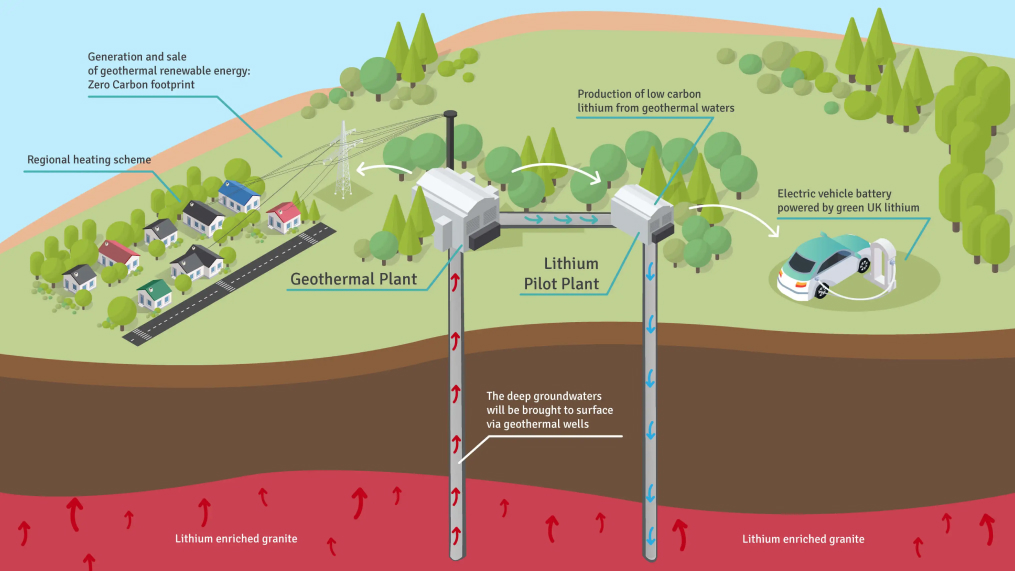

Compact, low-cost, and rapid operations could expand access to include new sources of lithium, such as disused oil and gas wells and geothermal brines, that are currently too small or too dilute for lithium extraction. The researchers said the accelerated evaporation rate could also allow for operation in more humid climates. They are even investigating whether the technology would allow for lithium extraction from seawater.

“Our process is like putting an evaporation pond on a string, allowing us to obtain lithium harvests with a significantly reduced spatial footprint and with more precise control of the process,” said Sunxiang (Sean) Zheng, study co-author and former Andlinger Center Distinguished Postdoctoral Fellow. “If scaled, we may open up new vistas for environmentally friendly lithium extraction.”

Since the materials to produce the strings are cheap and the technology does not require chemical treatments to operate, the researchers said that with additional enhancements, their approach would be a strong candidate for widespread adoption. In the paper, the researchers demonstrated the potential scalability of their approach by constructing an array of 100 lithium-extracting strings.

Ren’s team is already developing a second generation of the technique that will enable greater efficiency, higher throughput, and more control over the crystallization process. He credits the Princeton Catalysis Initiative for providing critical initial support to enable creative research collaborations. Additionally, his team recently received an NSF Partnerships for Innovation Award and an award from Princeton’s Intellectual Property (IP) Accelerator Fund to support the research and development process, including ways to modify the approach to extract other critical minerals in addition to lithium. Together with Kelsey Hatzell, assistant professor of mechanical and aerospace engineering and the Andlinger Center for Energy and the Environment, Ren also received seed funding from the Princeton Center for Complex Materials to better understand the crystallization process.

Zheng is leading the launch of a startup, PureLi Inc., to begin the process of refining the technology and eventually bringing it to the wider marketplace. Zheng was selected as one of four researchers in the inaugural START Entrepreneurs cohort at Princeton, an academic fellowship and startup accelerator designed to foster inclusive entrepreneurship.

“As a researcher, you know firsthand that many new technologies are too expensive or difficult to scale,” Zheng said. “But we are very excited about this one, and with some additional efficiency improvements, we think it has incredible potential to make a real impact on the world.”