Using Light to Create 3D Helical Nanostructures: A Simple and Scalable Approach

March 18, 2024

The Science X's editorial process and policies have come into play in reviewing this article. Editors have given special attention to the quality and credibility of the content, ensuring it is:

- fact-checked

- sourced from reliable authorities

- proofread

Patricia DeLacey, seasoned faculty at the University of Michigan College of Engineering, supervised this article.

A new production methodology for helical metal nanoparticles offers a faster, less expensive way to generate a crucial material for biomedical and optical devices, a study conducted by researchers at the University of Michigan reveals.

Nicholas Kotov, the Irving Langmuir Distinguished University Professor of Chemical Sciences and Engineering at U-M and co-corresponding author of the study says, 'Our aim is to greatly simplify the manufacturing process of complex materials that are currently holding back many emerging technologies.'

The study shows a new way to create Chiral surfaces— these do not have mirror symmetry (akin to a left and right hand)— possessing the capability to manipulate light on the nanoscale, a property highly sought after. This novel process includes 3D-printing 'forests' of nanoscale helices, alignment of which with a light beam induces potent optical rotation, making harnessing chirality achievable in the medical and informational technology spheres where chirality is prevalent.

Chiral surfaces created from plasmonic metals are even more sought after as they can generate a series of highly sensitive biotech detectors capable of detecting specific biomolecules produced by dangerous drug-resistant bacteria, mutated proteins, or DNA. These can aid in developing targeted therapeutics. Furthermore, they exhibit the potential to improve information technologies by promoting larger data storage capacities and expedited processing speeds through leveraging the light-electronic system interaction typified in fibre optic cables.

However, developing these much-needed, unique 3D-structured surfaces from the stand-up helices using traditional methodologies is complicated, costly, and produces lots of waste.

Typically, these are crafted using highly optimized hardware— such as two-photon 3D lithography or ion/electron-beam-induced deposition— available exclusively in certain high-end facilities. While precise, these methods necessitate laborious, multi-stage processing, incurring low pressure or high-temperature conditions.

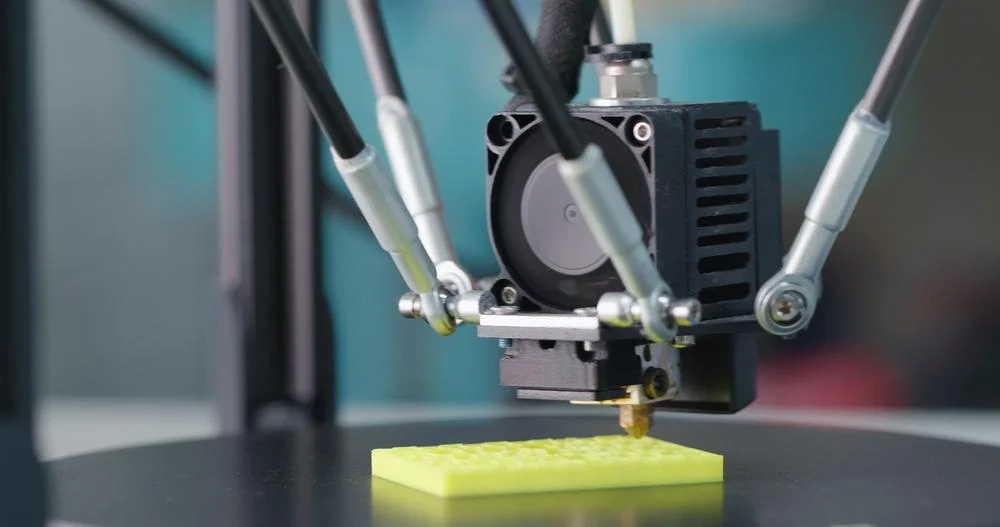

As a potential contender, 3D printing has been suggested, yet existing 3D printing technologies aren't capable of nanoscale resolution. To counter this, the U-M research team devised a method capitalizing on helical light beams to generate nanoscale helices with a specific twist and pitch.

Kotov commented that 'Within minutes, significant chiral plasmonic surfaces can be developed using cost-effective medium-powered lasers. It is fascinating to see the speed at which these helical forests sprout.'

The chiral structures' 3D printing by helical light builds on the light-to-matter chirality transfer discovery made at U-M about a decade ago.

A one-step, mask-free, direct method of printing from silver salt aqueous solutions, this circumvents the need for nanolithography while advancing 3D additive manufacturing. The easy processing, high polarization rotation and fine spatial resolution of light-driven printing of helices from the metal will considerably hasten the production of complex nanoscale architecture for future optical chips.

The article is provided by the University of Michigan College of Engineering.